Alpe del Garda Cooperative: environmental friendliness and territorial development

Surrounded by untouched nature, the Alpe del Garda Cooperative operates in absolute harmony with its surrounding territory, between the mountains that divide Tremosine from Trentino on one side and Lake Garda with the Baldo chain on the other, in the heart of the spectacular Alto Garda Bresciano regional park. Environmental friendliness and care for the local territory are fundamental values for the Alpe del Garda Cooperative, which identifies them, since it was established in 1980, as objectives of its business, along with developing farming and the local economy.

Surrounded by untouched nature, the Alpe del Garda Cooperative operates in absolute harmony with its surrounding territory, between the mountains that divide Tremosine from Trentino on one side and Lake Garda with the Baldo chain on the other, in the heart of the spectacular Alto Garda Bresciano regional park.

Environmental friendliness and care for the local territory are fundamental values for the Alpe del Garda Cooperative, which identifies them, since it was established in 1980, as objectives of its business, along with developing farming and the local economy.

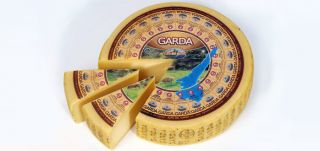

Specifically, the Cooperative’s cheese factory constitutes the perfect combination of ancient mountain traditions and cutting-edge technologies that allow the milk processing process to be monitored at all times, and ensure the most stringent application of all the applicable hygiene regulations.

It is precisely due to their reliability that Pieralisi technologies were selected, Renato Cassoni, director of the Cooperative, explains that “not only has the Pieralisi plant enabled us to achieve superior quality parameters, but its versatility has also allowed us to apply a processing technique linked to tradition that has allowed us to maintain and enhance the organoleptic characteristics of our cheeses”.

The Cooperative has a complete Pieralisi plant thanks to the turnkey formula, which includes the entire milk reception process at the cheese factory, with each 10.000-litre tank insulated and refrigerated, a Pieralisi MCS5 centrifuge combined with a Pieralisi PC70/4 pasteurizer.

In the cheese production area, 2 circular cheese vats were also supplied for the production of typical hard and semi-hard cheese (Formaggella di Tremosine).

The entire production process is managed by a PLC control panel which, depending on the recipes set, uses its own software to manage all the parameters, such as temperatures and time frames to obtain the desired cheese. Pieralisi also supplied the centrifuge for skimming the whey after the curd processing, specifically the skimmer mod. SV30.