The success of the Dutch company SMG in producing fertilizer

The success story of Stichting Mestverwerking Gelderland takes us to the Netherlands, with the typical windmills and endless stretches of unspoiled land. Let’s go back in time, precisely to the 1970s, when livestock farms offloaded their manure directly onto fields. This led to the contamination of streams and rivulets, so the Dutch Water Board took the initiative to build a specific processing plant.

Soon, processing plants were opened in Elspeet and Putten. These were followed in the early Nineties by the plant in Ede, and in 1994 SMG built its plant in Stroe. While several initiatives in the field were abandoned due to financial problems and problems with permits, SMG's plants proved to be profitable.

“The dry matter contained in manure has almost doubled over the years, from 1.8 to 3.5 percent, making it increasingly difficult to process” - explains Wim van Omme, the plant manager. invest €1.5 million in the new KGBI Stroe plant headquartered in Veluwe, by purchasing a new pre-sedimentation tank, a Pieralisi MAMMOTH 3 decanter centrifuge and a liquid storage tank. By 2017 - the director continues - we expect the new plant, which was completed in the last quarter of 2015, to be capable of processing 190,000 tonnes. Its capacity is actually 210,000 tonnes for future expansion, thereby giving KGBI Stroe a significant contribution in the processing of excess manure.”

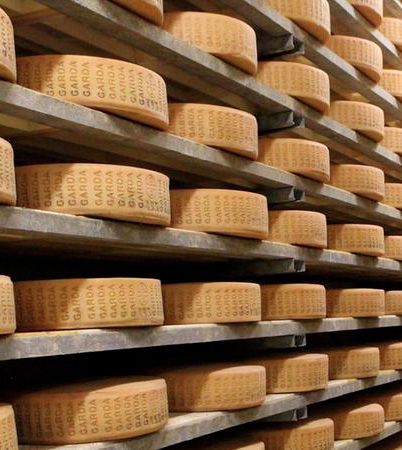

With this form of processing, SMG ensures that individual cattle farms can comply with the requirements of the Dutch Government which establish that part of their manure must necessarily be processed and exported. Nowhere else aside from the Netherlands is there a similar pre-sedimentation, dewatering and biological purification process, which not only supplies reusable products, but also a reduction in the environmental footprint. “The ammonia reduction amounts to up to 98%, as the ammonia is converted into nitrogen gas. Any water left over from processing is discharged into the sewers” explains Van Omme.

This results in a clear wave of improvement and efficiency in terms of environmental friendliness and for fertilizing quality.

To date, bearing in mind that most processes are largely automated, processing takes place continuously and it takes about two weeks for a reusable product to be completed. Supplies are brought in by tankers with about 110 loads each week. The cow manure arrives in a pre-sedimentation tank with a capacity of about 1,100 m3. The waste material settles overnight and passes into the liquid manure storage tank with a capacity of 4,000 m3. The same night, the settled part is pumped into the sediment tank and is then dehydrated by Pieralisi’s MAMMOTH 3 Pieralisi decanter centrifuge.

This investment is the result of the need to improve the cow manure processing process and the new machinery made it possible to produce top quality natural fertilizer. “We didn't have a single incident over 1,500 hours of activity”, director Van Omme concludes with satisfaction.

On their part, Pieralisi are satisfied and proud to be once again involved in an excellent modernisation process and a cutting-edge success story.